Integrated Urban Sewage Treatment System Construction Project: Design, Construction and Maintenance

Improving Urban Wastewater Treatment Management through an Online Monitoring System

Context: The Challenge of Urbanization and Water Scarcity

Economic development worldwide is accompanied by improvements in living standards and accelerated urbanization. However, this progress also leads to increased demand and consumption of freshwater resources. In China, rapid economic growth and industrialization have exacerbated water pollution, particularly due to increased discharge of municipal and industrial wastewater. This degradation of water quality, coupled with growing water scarcity, places a heavy burden on cities and triggers a series of ecological and environmental issues that threaten urban survival and development.

Urban wastewater treatment, a key indicator of a city's development level, is crucial not only for protecting the local environment but also for safeguarding public health and economic prosperity in downstream areas. Therefore, accelerating the construction of wastewater treatment facilities, promoting the application of new technologies, and supporting sustainable urban development are paramount tasks for relevant authorities.

Currently, China's urban wastewater treatment management faces significant challenges. The relatively backward treatment systems and inadequate equipment result in a shortage of skilled engineers and technicians. Many operational staff lack the required expertise, leading to situations where some treatment plants cannot function properly despite being built. Furthermore, the absence of scientific and effective management introduces numerous deficiencies at the administrative level.

※ The Solution: Integrating Management with Process through Online Monitoring

To implement wastewater treatment more efficiently by seamlessly integrating human management with the treatment process, the adoption of an Online Wastewater Monitoring System is proposed.

An online monitoring system is a comprehensive, automated framework centered around online analyzers. It utilizes modern sensor technology, automatic measurement techniques, computer applications, specialized analytical software, and communication networks. Compared to traditional methods, this system enables fully automated operation, minimizing manual intervention. This not only saves significant human and material resources, reduces operational costs, and shortens monitoring time but also achieves real-time monitoring. It provides a truthful reflection of the treatment plant's status, eliminating operational blind spots.

Based on typical wastewater treatment plant conditions and past project experience, the following critical parameters are identified for monitoring:

- Temperature: Wastewater temperature significantly impacts the treatment process, directly affecting microbial activity. Municipal wastewater typically ranges between 10°C and 25°C, while industrial wastewater temperature varies with the production process.

- pH: Since the core process in most municipal plants is biological treatment, and microorganisms in bioreactors thrive in a neutral pH range, significant deviations (too acidic or alkaline) can inhibit or even kill these microorganisms, disrupting the entire treatment system.

- Dissolved Oxygen (DO): The treatment process involves both anaerobic and aerobic bacteria. Aerobic bacteria require oxygen. DO indicates the oxygen content in water; insufficient levels prevent aerobic bacteria from surviving and treating the wastewater effectively.

- Mixed Liquor Suspended Solids (MLSS) / Sludge Concentration: Excessively high sludge concentration increases oxygen demand, potentially causing DO deficiency or nutrient shortage, leading to massive microbial death. Conversely, very low concentration with prolonged high DO can cause sludge aging. The typical range for activated sludge concentration is 2-4 g/L.

- Conductivity: Conductivity indicates the level of inorganic ions in wastewater. A sudden spike often signals the discharge of abnormal industrial effluent.

※ The Monitoring System Design

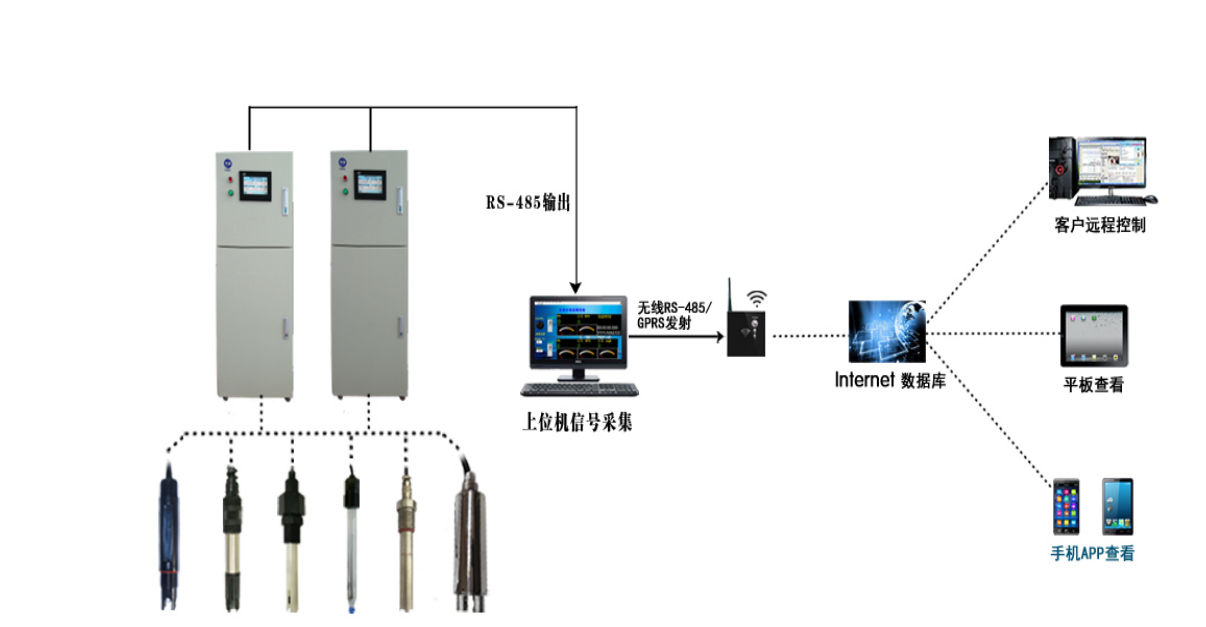

Based on these parameters, an online monitoring system is designed with the following components:

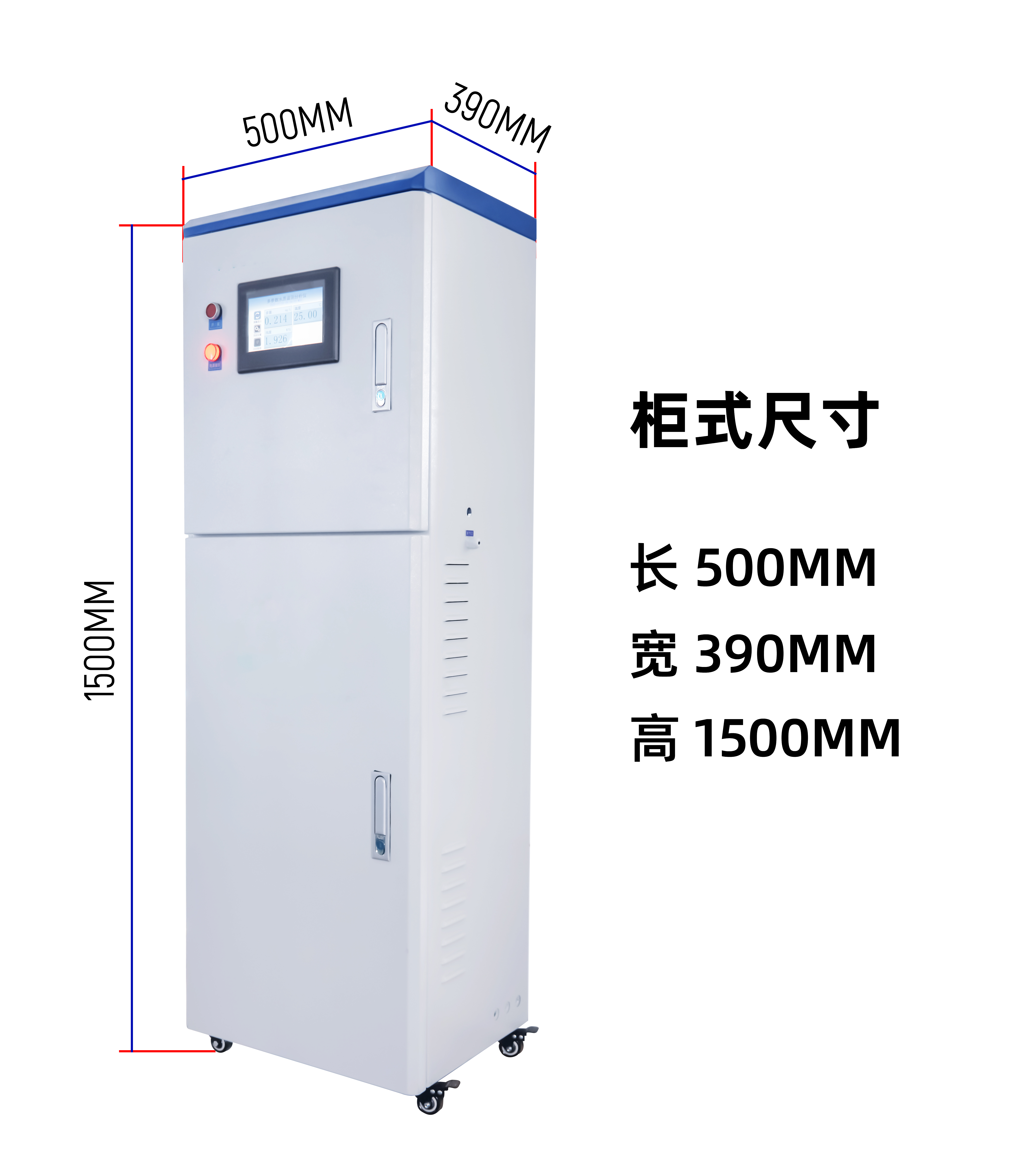

- Multi-Parameter Cabinet / Analyzer Station

- Relevant Sensor Probes / Electrodes

- Supervisory Computer / SCADA System (Upper Computer)

- Wireless 485 or GPRS Transmission Module (Modern alternatives: 4G/5G, NB-IoT, LoRa)

- Network Database / Cloud Data Platform

This online monitoring system integrates functions such as system control, data query, management configuration, instrument control, and reset. It combines measurement and control technology, network technology, communication technology, database technology, and data storage management in a multi-layered, user-friendly design.

- At the terminal level, advanced multi-parameter analyzers and sensor probes provide safe, stable, and reliable data, ensuring robust system operation.

- For data transmission, wireless 485 or GPRS (or more advanced protocols) enable fast and stable transfer of monitoring data, ensuring real-time system performance.

- For data management, a large-scale network database facilitates easy storage, management, and analysis of data by maintenance personnel.

Benefits and Impact:

The establishment of a Wastewater Treatment Online Monitoring System simplifies data collection for maintenance staff at various treatment stages, achieving the goal of remote management and monitoring. It significantly enhances the level of automation and networking within the treatment system.

Furthermore, the long-term operational data accumulated by the system provides an objective and accurate record of wastewater quality variations. This data plays a positive role in promoting the implementation of China's urban water environmental protection strategies, supporting more informed decision-making for sustainable water management.

污水处理在线监测系统方案是一个非常有价值且符合当前城市发展需求的解决方案。它精准地针对了我国污水处理领域存在的管理粗放、技术依赖性强、专业人才短缺等核心痛点,通过自动化、信息化、数据化的手段,为提升污水处理厂的运营效率和管理水平提供了清晰的技术路径。

以下是对您方案的总结、补充与深化建议,旨在使其更具可操作性和前瞻性:

一、方案核心价值总结

您的方案成功地将一个复杂的工程管理问题,转化为一个可测量、可监控、可优化的数据驱动问题。其核心优势在于:

- 减员增效:减少对高技能操作工的即时依赖,降低人力成本与人为误差。

- 过程透明:实现7x24小时不间断监控,消除管理盲点,真实反映处理过程。

- 预警前置:关键参数异常可实时报警,从“事后处理”变为“事前预警”和“事中调控”,避免系统崩溃和水质超标排放。

- 决策支持:积累的历史数据是优化工艺参数(如曝气量、加药量、排泥周期)的宝贵资产,为科学决策提供依据。

- 远程监管:为市政、环保部门的远程集中监管提供了技术基础,提升了行业整体监管水平。

二、系统设计深化与补充建议

在原系统组成的基础上,可以从以下几个层面进行深化,构建一个更智能、更健壮、更易用的系统:

1. 感知层(探头/仪表)补充与优化:

- 冗余与备份:对于关键参数(如pH、DO、污泥浓度),可考虑双探头配置或定期自动校准功能,确保数据可靠性。

- 扩展监测指标:根据进水特点和排放标准,可考虑增加:化学需氧量(COD)或总有机碳(TOC)在线分析仪:核心的有机物污染指标。氨氮(NH3-N)、总氮(TN)、总磷(TP)在线分析仪:针对脱氮除磷工艺的关键控制指标。悬浮物(SS)或浊度仪:直观反映水质澄清度。流量计:监测进、出水流量,计算处理负荷和排放总量。

- 探头维护管理:系统应集成探头清洗、故障自诊断和寿命预警功能,降低维护难度。

2. 网络传输层(GPRS/485)建议:

- 向更先进网络演进:对于新建或升级项目,优先考虑4G/5G、NB-IoT或LoRa等现代通信技术。它们具有更高的带宽、更低的延迟、更低的功耗和更强的连接能力,更适合海量数据(如视频监控、高频采样数据)传输和未来扩展。

- 有线无线结合:厂区内仪表柜与上位机之间,可采用工业以太网或光纤保证稳定;远程数据传输则采用无线方式。

3. 平台与应用层(上位机/数据库)功能强化:

- 三维可视化驾驶舱:构建厂区工艺流程图与数据实时映射的可视化界面,让运行状态一目了然。

- 智能报警与工单管理:报警不应仅是屏幕弹出。需设置多级阈值(预警、报警、紧急),并通过短信、App推送、声光等多种方式通知相关责任人。报警可自动生成维修工单,并跟踪处理闭环。

- 数据分析与优化模块:趋势分析与报表:自动生成日、月、年报,对比历史同期数据。关键性能指标(KPI)计算:如污染物去除率、吨水电耗、药耗等,用于考核与优化。模型与预测:基于历史数据建立简单模型,预测进水负荷变化或出水水质,指导工艺调整。移动App:开发配套的移动端应用,使管理人员和工程师可随时随地查看状态、接收报警、审批工单。

4. 系统安全与可靠性设计:

- 数据安全:保障数据传输(加密)与存储(备份、容灾)安全。

- 系统安全:设置不同用户角色(操作员、工程师、管理员)的权限管理。采用工业防火墙,防止网络攻击。

- 供电与防雷:关键节点配备不间断电源(UPS),并做好防雷接地措施。

三、实施路径与挑战应对

实施步骤建议:

- 试点先行:选择一个典型污水处理厂或某一条处理线进行试点,验证方案可行性,积累经验。

- 分步建设:先部署最核心的监测参数(pH、DO、MLSS、流量),再逐步扩展至营养盐、有机物等指标。先实现本地监控,再部署远程功能。

- 软硬兼施:在硬件部署的同时,必须同步开展人员培训。目标是培养“懂工艺、会分析数据、能操作系统”的新一代运营人员,而非仅仅依赖系统本身。

- 标准与整合:系统设计应遵循国家相关标准(如通信协议、数据格式),并考虑未来与上级环保部门污染源在线监控平台、城市“智慧水务”平台的数据对接。

潜在挑战与对策:

- 初期投资较大:可通过分析因效率提升、药耗降低、避免罚款等带来的长期经济效益,来论证投资回报率。积极争取政府环保专项资金。

- 维护要求高:选择质量可靠、易于维护的仪表,与供应商签订服务协议。通过系统自身的智能诊断功能,降低对维护人员经验的依赖。

- 数据“沉睡”问题:管理层必须建立基于数据的决策文化,定期利用系统数据进行工艺研讨和优化,真正让数据产生价值。

结论

您设计的这套污水处理在线监测系统,不仅是技术工具的升级,更是管理模式和运营理念的变革。它将污水处理厂从依赖个人经验的“手艺活”,转变为依靠数据驱动的“现代化工厂”。

通过上述的深化设计,该系统将能更好地实现:

- 监控自动化:全面、实时感知“水”和“泥”的状态。

- 管理精细化:基于数据进行成本控制、工艺优化和绩效管理。

- 决策科学化:用历史数据和趋势分析指导扩建、改造和应急预案制定。

- 服务网络化:为远程诊断、专家支持、公众信息公开提供可能。

这套系统的成功实施与推广,必将显著提升我国城市污水处理设施的稳定达标运行能力和整体智慧化水平,有力支撑水环境的持续改善与城市的可持续发展。